As consumer demand for specialty and high-quality breads continues to grow across the Northeast, bakeries must adapt by utilizing conveyor belts that enhance efficiency, hygiene, and performance. The right conveyor belt plays a critical role in producing everything from artisan sourdough in New York to gluten-free loaves in Pennsylvania.

At RW Connection, we understand the unique challenges bakeries face and offer a range of industry-leading conveyor belting solutions to keep production lines running smoothly, safely, and efficiently.

Key Factors in Choosing the Right Bakery Conveyor Belt

1️⃣ Flexibility for Seamless Transitions

In bakery production, flexibility is essential for smooth product transfers between different stages of the baking process. Whether handling delicate dough transfers over a knife edge or transporting finished loaves on a rolling nose bar, the right belt ensures:

✔ Minimal product loss

✔ Improved throughput

✔ Efficient, high-speed production

For bakeries with high-speed automated production, selecting a belt with the correct flexibility and durability is crucial to maintaining consistent quality and efficiency.

2️⃣ Optimizing Grip, Release, and Feed Rates

A bakery conveyor belt must provide the right balance of grip and release to prevent sticking, tearing, or deformation of baked goods. The correct fabric and compound ensures proper dough handling throughout key processes, including:

✔ Sheeting & molding – Preventing tearing or sticking during shaping.

✔ Proofing – Providing gentle support while allowing controlled expansion.

✔ Cooling & packaging – Ensuring efficient transfer without contamination.

For high-output bakeries in the Northeast, selecting belts with optimized release properties helps reduce waste and maintain uniform product quality.

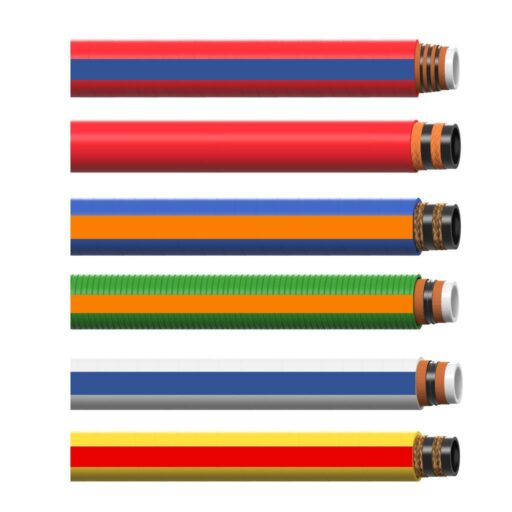

3️⃣ Belt Compatibility with Ingredients & Baking Conditions

Bakery environments expose conveyor belts to moisture, extreme temperatures, and oils, which can degrade the belt if the wrong material is used. From proofing to baking and cooling, belts must be resistant to:

🔥 High heat – Withstanding oven temperatures without warping or degrading.

💧 Humidity & moisture – Preventing bacterial growth in proofing chambers.

🛢️ Oils & greases – Resisting absorption for easy cleaning and sanitation.

Manufacturers like Habasit, Modutech, and Volta design specialty food-grade conveyor belts that handle these conditions while maintaining durability and compliance with food safety standards.

4️⃣ Compliance with Food Safety Standards in the Northeast

The Northeast has some of the strictest food safety regulations in the country, requiring bakeries to use conveyor belts that comply with FDA and USDA food safety guidelines.

🔹 Non-porous, easy-to-clean materials reduce the risk of bacterial contamination.

🔹 HACCP-compliant belts help bakeries meet stringent food processing standards.

🔹 Seamless, thermoplastic belts eliminate crevices where debris and bacteria can accumulate.

Choosing the right belt ensures safe, sanitary, and regulation-compliant operations across New York, Pennsylvania, New Jersey, and beyond.

Why Choose RW Connection?

At RW Connection, we specialize in high-performance bakery conveyor belts tailored to the needs of the Northeast’s growing baking industry. Whether you run a local artisan bakery in Boston or a high-volume bread production facility in Philadelphia, we can help you select the best belting solutions for your specific requirements.

✔ Industry-leading food-grade belts from Habasit, Modutech, and Volta

✔ Expert guidance in selecting the right belt for your production process

✔ Fast turnaround times and reliable customer support

Contact RW Connection Today!

Looking for reliable, food-safe conveyor belts for your bakery? Contact RW Connection today to learn how our premium conveyor belting solutions can enhance your production process and help you meet increasing market demands across the Northeast!