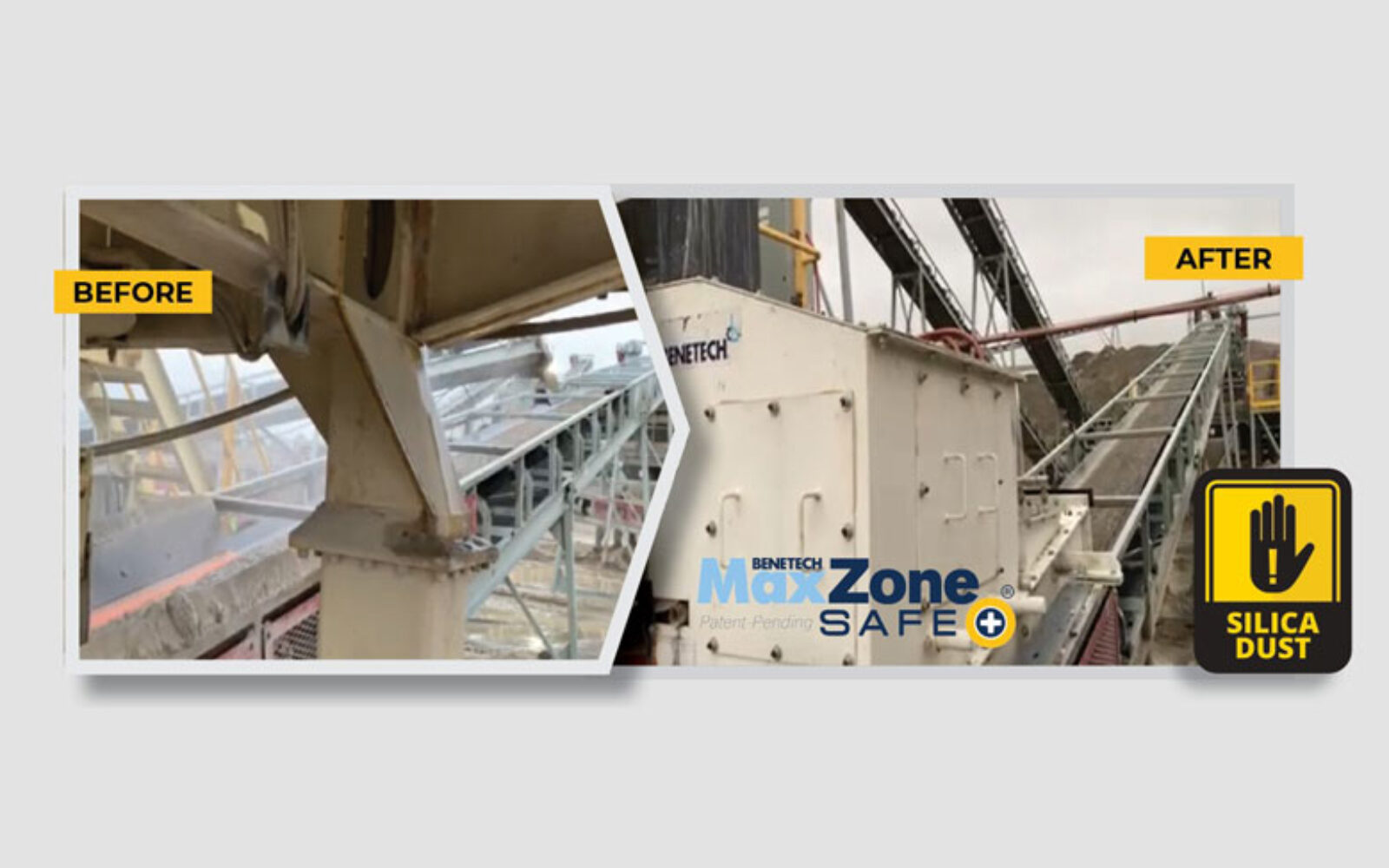

Dust suppression is a critical concern in the aggregate mining industry, affecting worker safety, equipment efficiency, and regulatory compliance. Uncontrolled dust—especially Silica Dust—can lead to serious health hazards and operational inefficiencies. RW Connection provides industry-leading dust suppression solutions from Benetech, helping mining operations across the Northeast implement effective, compliant, and efficient dust control strategies.

The Risks of Silica Dust Exposure

Silica dust is a fine particulate generated during aggregate mining and material handling, and prolonged exposure can cause serious respiratory diseases, including:

❌ Silicosis – A lung disease caused by inhaling crystalline silica particles.

❌ Lung Cancer – Long-term exposure increases the risk of cancer.

❌ Chronic Obstructive Pulmonary Disease (COPD) – Causes long-term lung damage, reducing breathing capacity.

The Occupational Safety and Health Administration (OSHA) has set strict regulations to limit worker exposure to respirable crystalline silica. Non-compliance can lead to significant fines and legal penalties, making effective dust suppression a necessity for mining operations.

How Benetech’s Dust Suppression Systems Improve Safety & Efficiency

Benetech offers innovative, high-performance dust suppression solutions to help aggregate and mining operations control airborne dust and mitigate health risks. These include:

💦 Wet Dust Suppression Systems – Use water sprays and misting systems to control dust at material transfer points, crushers, and conveyor belts.

🫧 Foam Dust Suppression – Encapsulates fine dust particles with a foam barrier, significantly reducing dust emissions while minimizing water usage.

🧪 Dust Control Chemicals – Specialized chemical treatments enhance water’s dust suppression capabilities while preventing material buildup.

🚧 Enclosed Transfer Points – Dust curtains, sealed conveyor transfer points, and belt enclosures prevent dust from escaping into the environment.

Key Benefits of Benetech Dust Suppression Solutions

✔ Improved Worker Health & Safety – Reduces silica dust exposure, helping operations stay compliant with OSHA regulations.

✔ Extended Equipment Life – Prevents dust buildup in conveyors, crushers, and material handling components, reducing wear and tear.

✔ Regulatory Compliance – Ensures operations meet EPA and MSHA air quality standards, avoiding costly fines.

✔ Enhanced Visibility & Safety – Reduces airborne dust clouds, improving visibility on mining sites and reducing accident risks.

✔ Increased Operational Efficiency – Limits dust accumulation, reducing cleanup efforts and maintenance downtime.

Frequently Asked Questions (FAQs)

✅ Q1: How does silica dust impact worker health?

A: Silica dust is highly hazardous and can cause lung diseases such as silicosis, lung cancer, and COPD. Long-term exposure significantly increases health risks for workers.

✅ Q2: What are the OSHA regulations for silica dust exposure?

A: OSHA’s Respirable Crystalline Silica Standard limits worker exposure to 50 micrograms per cubic meter over an 8-hour shift. Employers must implement engineering controls and protective measures to stay compliant.

✅ Q3: How do Benetech’s dust suppression solutions work?

A: Benetech’s solutions capture and control dust particles at the source using water misting, foam suppression, and chemical treatments, preventing dust from becoming airborne.

✅ Q4: Will dust suppression systems increase water usage?

A: Not necessarily. Foam and chemical dust control solutions reduce water consumption while maximizing dust suppression efficiency.

✅ Q5: Can dust suppression help lower maintenance costs?

A: Yes! By minimizing dust buildup on conveyors, crushers, and material handling equipment, maintenance costs and downtime are significantly reduced.

Why Choose RW Connection for Dust Suppression Solutions?

At RW Connection, we supply high-performance conveyor components and dust control solutions to ensure safe, efficient mining operations across the Northeast. Partnering with Benetech, we help businesses:

✔ Improve workplace safety with effective silica dust control.

✔ Extend the lifespan of conveyor components and processing equipment.

✔ Ensure compliance with OSHA, EPA, and MSHA regulations.

✔ Boost efficiency with reduced maintenance and downtime.

Get the Right Dust Suppression System for Your Site!

Looking for reliable dust control solutions for your aggregate mining operation? Contact RW Connection today to learn more about Benetech’s industry-leading dust suppression systems and how they can enhance safety, compliance, and operational efficiency!