Large & Craft Breweries

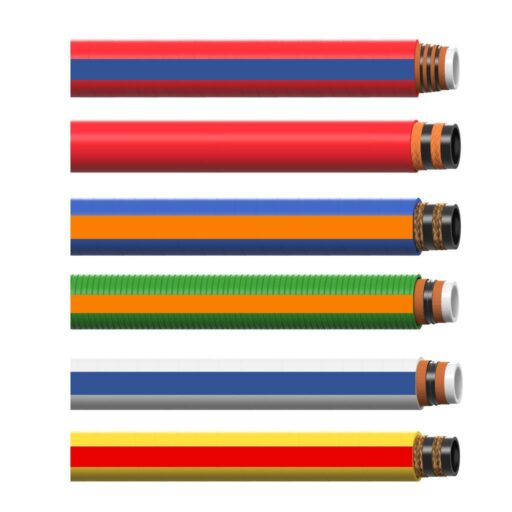

The brewery industry relies heavily on high-quality brewery and washdown hoses to maintain efficient operations and ensure product integrity. From transferring raw ingredients to moving finished beer between tanks, these hoses are a critical part of daily production. Using top-grade brewery hoses helps prevent contamination, as they are designed without rubber compounds or plasticizers that can leach into the product and alter the flavor profile of the beer. In addition, durable washdown hoses are essential for maintaining strict sanitation standards throughout the facility. With the right hose solutions, breweries can safeguard the taste and consistency of their craft while keeping operations clean, compliant, and running smoothly.