The Importance of Hose Identification & Safety

Industrial equipment is becoming larger, faster, and more complex—and keeping teams safe while maintaining efficiency is more critical than ever. RW Connection is committed to providing industry-leading hose management solutions, including color-coded hoses and couplings. This simple yet highly effective visual identification system helps teams:

✔ Improve safety

✔ Reduce connection errors

✔ Prevent cross-contamination

✔ Streamline maintenance and inspections

How Can Color Coding Improve Workplace Safety?

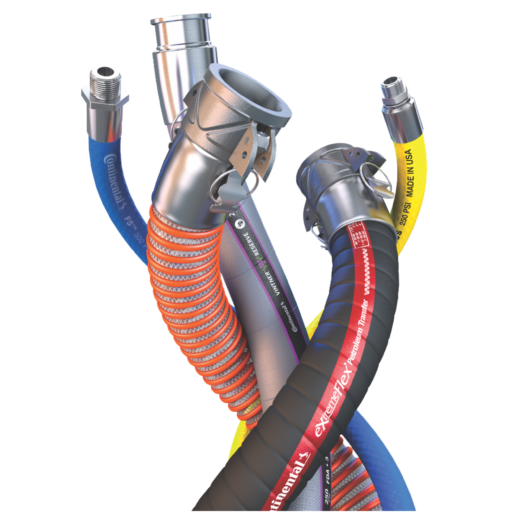

1️⃣ Clear Identification of Media Conveyed

Using a color-coded system helps teams quickly recognize what is flowing through each hose, reducing the risk of cross-contamination or hazardous exposure. For example:

- Green Hose – Hydrochloric Acid (HCL)

- Blue Hose – Potable Water

- Orange Hose – Peroxide Solution

By incorporating a standardized visual system, teams can instantly verify hose usage, improving efficiency and safety.

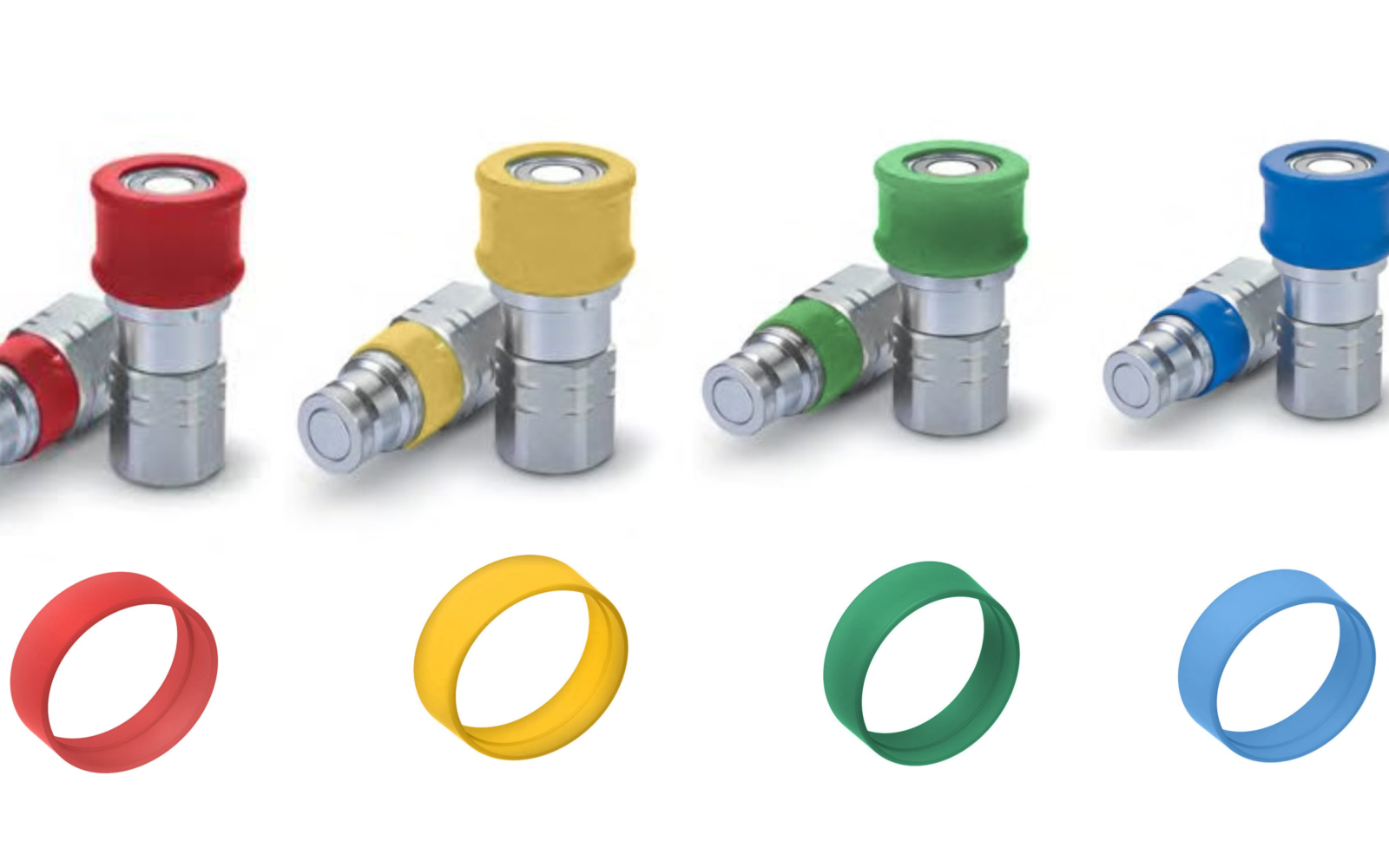

2️⃣ Faster Equipment & Accessory Changeouts

In industries like construction, mining, and manufacturing, equipment relies on quick disconnect hydraulic couplings. Color-coded couplings or hose tags ensure that workers:

✔ Avoid incorrect hydraulic hose connections

✔ Prevent flow reversal, which can cause malfunctions or safety risks

✔ Reduce downtime by quickly identifying proper connections

3️⃣ Asset Management & Maintenance Tracking

Hose failures often result from missed inspections or outdated maintenance schedules. Color-coded hoses based on inspection or test dates help teams:

✔ Easily track service intervals

✔ Identify hoses due for testing or replacement

✔ Improve inspection efficiency in large facilities

If you aren’t using our OnGuard™ Hose Management System, contact us today to learn how it can simplify your preventative maintenance program.

4️⃣ Enhanced Training for New Employees

New hires often need time to learn industrial hose systems. Color-coded application charts can help new employees:

✔ Identify hoses quickly

✔ Follow work instructions more easily

✔ Reduce training time and errors

By implementing a standardized color system, companies can boost workplace safety and efficiency while reducing costly mistakes.

Make Color Coding a Part of Your Safety Culture

At its core, color coding is about efficiency, safety, and organization. Implementing this simple yet highly effective system provides:

✔ Faster equipment swaps with easy-to-identify couplings

✔ Prevention of cross-contamination & incorrect connections

✔ Simplified maintenance tracking for reduced downtime

In an industry where every second and every dollar counts, color coding is a small investment that delivers big results.

Want to improve hose safety and management? Contact RW Connection today to discuss color-coded hoses, asset-tracking solutions, and our OnGuard™ Hose Management Program.